-

22

Jul

Tag, Scan & Repeat: The Simplicity and Added Value of Traceability

Whenever the topic of traceability in the supply chain comes up, many often perceive it as tracking the logistics of deliveries and shipments. However, in light of Industry Transformation 4.0, traceability in the supply chain has evolved beyond the basic tracking mechanisms of physical cargo or items in transit.

Traceability is now about providing a full spectrum of transparency and visibility to create trust and confidence in all stakeholders involved in the supply chain of goods.

Thus, traceability is the ability to track and trace a batch of goods from its raw material production right through to when it reaches the hands of the end-users. The system is capable of recording and reporting every procedure along the supply chain, such as history, distribution path and location, and raw material and parts information.

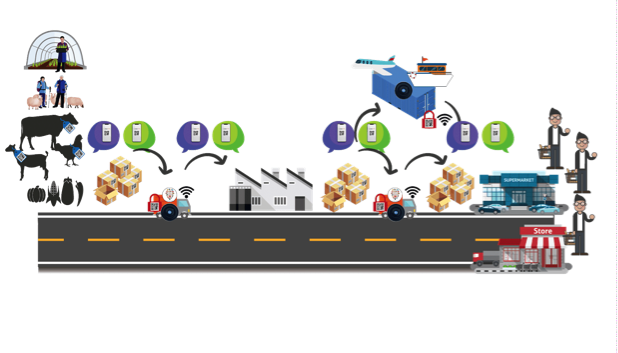

Despite massive leaps of technology advancements with regards to traceability, the mechanism for traceability for those involved in the supply chains remains simple yet comprehensive: tag, scan, and repeat. By going through these steps at every stage of the supply chain, from raw materials sources through to the shelves of retailers, products and related information are retrieved, registered, and made available for business owners and consumers to trace and track.

The ability to register and store information within a secure and real-time database establishes information and knowledge sharing with all parties on the “what, when, where, and how” of a product.

Image 1: Mud crab in Australia is being tagged to allow the monitoring of sustainable fishing.

As a supply chain industry player ourselves, we have captured an expanding trend on the demand for QR codes over the last three years. With these insights, we have shifted our traceability implementation by simply replacing the conventional barcodes and serial numbers on our security seals with QR codes. The information behind the QR code will then be registered into a user-friendly system that can be accessed by anyone along the supply chain, without the need of a specialised barcode scanner.

Through the integration of hardware (security seals and stickers) and software (QR code and a monitoring platform), business owners are equipped and ready to deploy this value-added feature into their business, granting them more control and increasing their credibility amongst stakeholders and consumers.

Image 2: When the industry starts tagging all goods/items with its details uploaded and accessible via a QR code, authorities, business owners, and end-users will have full transparency of the supply chain; thus are empowered with traceability.

Business owners who take advantage of the real-time features of the traceability system are able to make timely decisions to avoid loss and prevent disruption when alerts are triggered. By generating the data and history that are securely stored in the system, business owners can navigate through potential risks through improving operational procedures and enhancing resilient planning.

Image 3: Mega Fortris’ Fast Seal with a laser-engraved QR code that is unique to hold product details.

As another added value, by implementing transparency through traceability systems, organisations will also effectively demonstrate their sustainability initiatives and openness to stakeholders.